Producing quality

QUALITY MEANS TO US THE COMPLETE FULFILMENT OF ALL OF OUR CUSTOMER'S EXPECTATIONS; FOR WHOM WE PERFORM SERVICES. IT HEREBY APPLIES NOT TO CONTROL QUALITY, BUT TO PRODUCE IT!

EACH OF OUR QUALIFIED EMPLOYEES ASSUMES RESPONSIBILITY FOR THIS IN HIS OR HER FIELD.

For 40 years our demand has remained the same: 100% Quality Made in Germany

A permanent quality assurance is through:

- Use of steels in compliance with DIN 50049/3.1

- Digital measuring technology

- Records of all welding procedures

Perfect planning

Perfect planning

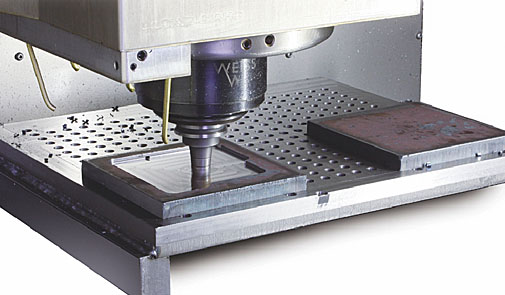

With modern CAD systems clearly defined tender and workshop drawings are produced. The CAM software used for the automatic milling process guaranties short programming times and optimum milling results.

ALSO USE THE DECISIVE ADVANTAGES OF OUR CONVENIENTLY SITUATED LOCATION IN GERMANY:

- Easily accessible transport routes

- High flexibility

- Rapid communication

- Close customer service

The achieved tolerances make the fitting of the stamping plates superfluous. The space between the mold and stamp can be determined in advance.

Optimised milling strategies and hardening techniques ensure the high product quality of our molds.

- Ideal surface properties

- Good dynamic behaviour

- Exact measurement and contours

- Very long stand times